Why Quality Matters: Insights from Leading DTF Printer Manufacturers

- Share

- Issue Time

- Aug 14,2024

Summary

But as with any printing technology, the quality of the DTF printer is critical. In this article, we will detail some relevant information about DTF printers.

Direct to Film printing has been a game-changer in the textile printing space. With the ability to produce vibrant, high-quality prints on a wide range of fabrics, it's no surprise that the technology is growing in popularity. But as with any printing technology, quality is critical. Why? Because the quality of your prints can make or break your business.

Learn about DTF Printing

DTF printing involves printing a pattern onto a special film and then transferring it to the fabric using heat and pressure. This process allows for complex patterns and vibrant colors that are difficult to achieve with other printing methods.

Here's a quick overview of the DTF printing process: First, the pattern is printed onto a PET film with a special ink. Then, a layer of adhesive powder is applied over the wet ink. The film is then heated to melt the adhesive, bonding the ink to the film. Finally, a heat press is used to transfer the film to the fabric.

DTF printing offers a variety of benefits, including the ability to print on a wide range of fabrics, high color vibrancy, and durability. Unlike screen printing, which requires a separate screen for each color, DTF printing can easily handle complex, multi-color designs.

Key Factors Affecting DTF Print Quality

Printer Specifications and Features

The quality of direct-to-film prints depends largely on the printer you choose. A high-resolution printer with advanced features is essential for achieving sharp, detailed images. Key specifications to look for include adjustable ink density settings, which allow you to control the intensity and saturation of colors, and print speed settings, which affect production quality and efficiency. Temperature control is another important feature, as it helps regulate the heat used during the transfer process, ensuring optimal adhesion and color fidelity. Additionally, consider printers with auto-calibration features, which can help maintain consistency and reduce the need for manual adjustments.

Ink Quality and Its Impact

The type of ink you use is just as important as the printer itself. Not all DTF inks are created equal, and their quality can greatly affect the final output. High-quality inks are designed to provide excellent color accuracy and vibrancy, ensuring that your prints reflect the true colors of your design. They also help improve the durability of your prints, making them more resistant to fading and wear. Premium inks have better adhesion and are less likely to suffer from issues such as smudging or bleeding, which can detract from the overall appearance of your prints.

Films and Transfer Materials

The selection of films and transfer materials is critical to achieving high-quality DTF printing. High-quality PET films are designed to work seamlessly with DTF inks and printers, providing a smooth surface that enhances the transfer of color and detail. These films should be compatible with your specific printer and ink type to ensure proper adhesion and vibrant results. Additionally, the quality of the transfer powder or adhesive used can affect how well the ink adheres to the film and subsequently to the fabric. Using quality materials minimizes issues such as peeling, cracking, or color bleeding, which can affect the longevity and visual appeal of your prints.

Calibration and Maintenance

Proper calibration and maintenance of your DTF printer is essential to maintaining consistent print quality over time. Regularly cleaning the printhead is essential to prevent clogging and ensure smooth ink flow, which directly affects print clarity and color accuracy. Frequently checking ink levels can help avoid issues such as inconsistent color application or printhead damage. Additionally, ensure that all printer components, such as rollers and alignment guides, are properly aligned and functioning properly. A regular maintenance program, including software updates and mechanical inspections, can help identify and resolve potential issues before they affect print quality.

The Role of Leading DTF Printer Manufacturers

Commitment to Quality Control

For leading DTF printer manufacturers, quality control is more than just a step in the process, it is a fundamental commitment throughout every stage of production. It starts with the careful selection and testing of raw materials to ensure they meet high durability and performance standards. Manufacturers use rigorous testing protocols to evaluate the compatibility of materials, inks, and films before approving them for production. Once production begins, each printer goes through a detailed inspection process that includes checks for accuracy, functionality, and overall build quality. This attention to detail helps prevent defects and ensures that each printer meets strict quality benchmarks before it reaches the hands of customers.

Advanced Technology and Innovation

Innovation is a hallmark of the top DTF printer manufacturers. These companies continuously invest in research and development to stay ahead of the curve in printing technology. They explore new materials, improve printing processes, and develop advanced features to improve printing quality, speed, and efficiency. Cutting-edge technology may include enhanced printhead designs for finer details, improved temperature control systems for better adhesion, or advanced software for more accurate color reproduction. By adopting the latest technology, leading manufacturers ensure that their products provide customers with superior performance, reliability, and value.

Customer Feedback and Continuous Improvement

Customer feedback is the cornerstone of continuous improvement for leading DTF printer manufacturers. These companies actively solicit and analyze user feedback to identify areas for improvement. They use this feedback to drive product development, making necessary adjustments to address user concerns and preferences. This may involve improving existing features, adding new features, or improving the user interface based on real-world experience. By maintaining an open dialogue with customers and incorporating their insights into product upgrades, manufacturers can better meet changing needs and expectations, ultimately providing more effective and user-friendly solutions.

How to Ensure High-Quality Results for DTF Printing

Choosing the Right Equipment

Investing in the right DTF printer is essential to achieving high-quality results. Look for a printer with high resolution, reliable performance, and support for the latest printing technologies.

Best Practices for Ink and Film Usage

Follow best practices for using ink and film to ensure the best results. This includes using compatible materials, following manufacturer guidelines, and performing regular maintenance on the printer.

Regular Maintenance and Troubleshooting Tips

Routine maintenance and troubleshooting are key to maintaining print quality. Clean the printer regularly, check for any issues, and resolve them promptly to avoid any interruptions in the printing process.

Conclusion

Quality is critical to DTF printing as it affects the appearance, durability, and overall performance of the final product. Investing in high-quality equipment, materials, and practices will ensure that you get the best results.

As DTF printing technology advances, maintaining high-quality standards will remain critical. By focusing on quality, you can not only enhance the quality of your products but also establish a good reputation in the market. If you are looking for a reliable DTF printer manufacturer, welcome to contact us.

Choosing FCOLOR for your DTF printing needs demonstrates our commitment to excellence, efficiency, and innovation. You are establishing a partnership that prioritizes your success and growth. Our extensive experience in the industry ensures that we understand the unique challenges and needs of high-volume printing operations. By partnering with FCOLOR, an inkjet printer and ink manufacturer, you will receive a comprehensive range of products and services designed to streamline your printing process and take your business to new heights.

At FCOLOR, we pride ourselves on providing more than just inks and equipment; we also provide tailor-made solutions and unparalleled support to help you maximize productivity and achieve outstanding results. Our team of experts is committed to providing personalized assistance every step of the way, from selecting products that fit your specific needs to optimizing your workflow for maximum efficiency.

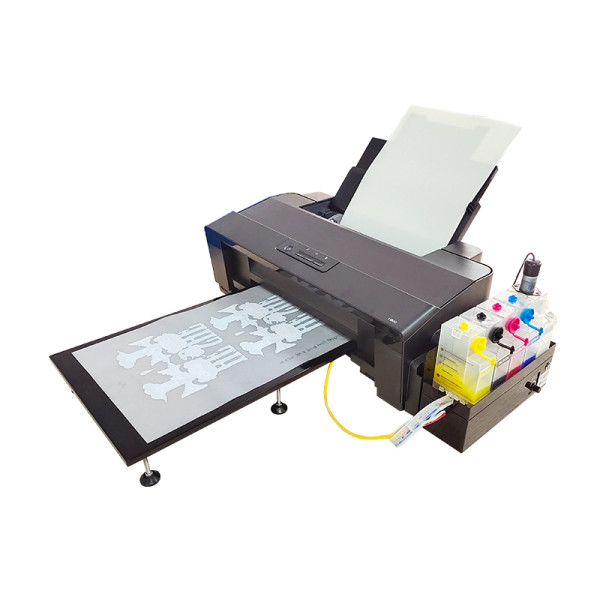

DTF printer High precision nozzle printing clearer image 60cm roll to roll direct to film printer

FCOLOR A3 DTF Dual XP600 Printer for T-Shirts - OEM/ODM, Wholesale Partnerships & Agent Support.

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

FCOLOR L8050 A4 DTF printing machine for clothing printing support OEM&ODM