Sublimation Ink Health and Safety Precautions

- Share

- Issue Time

- Apr 2,2024

Summary

The health concerns associated with sublimation ink cannot be ignored. Below we take a closer look at the risks of sublimation ink exposure and the associated safety measures.

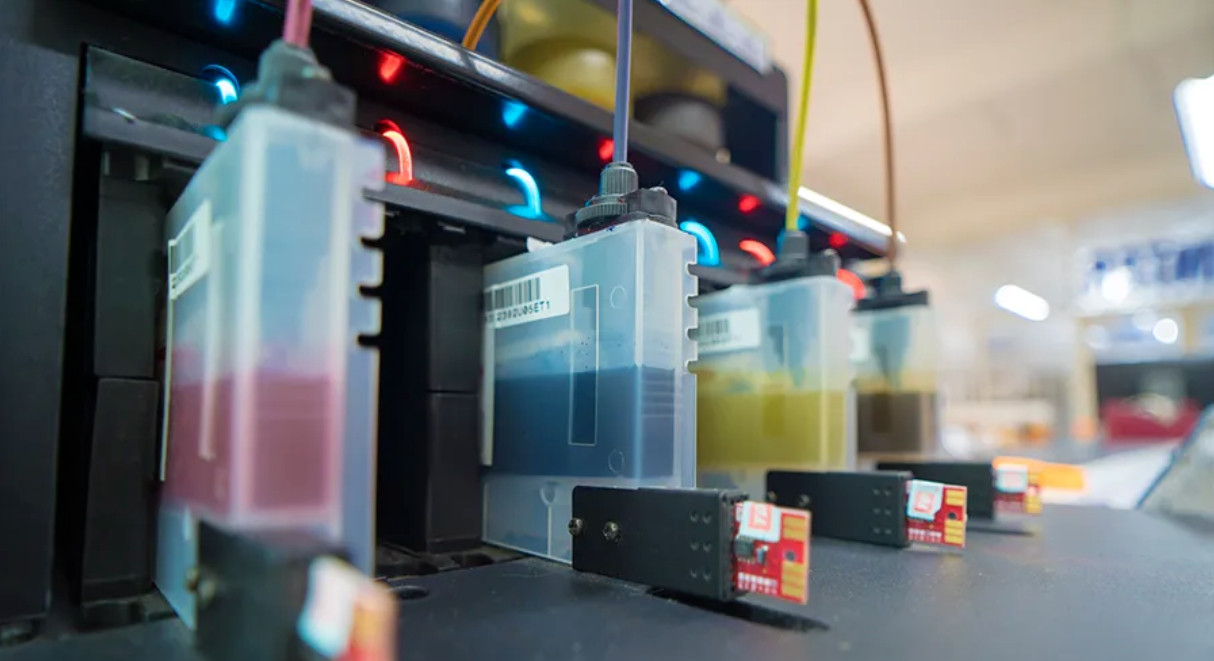

Dye-sublimation printing powered by dye-sublimation printers has revolutionized the world of custom printing, enabling vibrant and durable designs on a variety of surfaces. However, amid the excitement of creating stunning prints, it's important not to overlook the health and safety considerations associated with sublimation ink. In this article, we'll take a closer look at the potential risks of sublimation ink exposure, safety measures to mitigate these risks, environmental impacts, regulatory compliance, and best practices for safe use.

Safety Precautions When Handling Sublimation Ink

Wear Personal Protective Equipment (PPE): When handling sublimation ink, always wear appropriate personal protective equipment, including gloves, goggles, and a respirator. This helps prevent skin contact, inhalation of vapors, and eye contact.

Ensure Adequate Ventilation: Work in a well-ventilated area or use an exhaust ventilation system to minimize contact with ink vapors. Proper ventilation helps prevent harmful fumes from building up in your workspace.

Practice safe storage and handling: Store sublimation ink containers sealed in a cool, dry place away from heat sources and incompatible materials. When handling ink, avoid spills and leaks. If there is an accident, clean it up in time to prevent exposure.

Common Misunderstandings About Sublimation Ink

Sublimation Ink Is Harmless Because It Is Water-Based: A common misconception is that sublimation ink is completely safe because it is water-based. While many sublimation ink recipes do contain water as a carrier, they also contain other chemicals and dyes. These ingredients, if improperly handled or used, may pose health risks through inhalation, skin contact, or ingestion. It is important to realize that the water-based nature of sublimation ink does not eliminate its potential hazards.

Sublimation Inks Do Not Emit Harmful Vapors: Another misconception is that sublimation inks do not emit harmful vapors during the printing process. While sublimation inks don't produce as many volatile organic compounds (VOCs) as solvent-based inks do, they still release vapors containing dye particles and other chemicals when heated. Prolonged exposure to these vapors in poorly ventilated spaces can cause respiratory irritation and other health problems. Proper ventilation and respiratory protection are necessary precautions when working with sublimation ink.

Sublimation Ink Is Safe to Pour Down the Drain: Some people mistakenly believe that it is safe to pour leftover sublimation ink down the drain. However, this can have harmful consequences for the environment. Sublimation ink contains chemical additives and dyes that can pollute water sources and harm aquatic ecosystems. Proper disposal methods, such as recycling or hazardous waste disposal, should be followed to minimize environmental impact. Additionally, local regulations may prohibit disposing of ink waste into sewers, so it is important to check and follow applicable guidelines.

Chemical Ingredients in Sublimation Ink

Sublimation inks are composed of a carefully formulated blend of complex ingredients to achieve vibrant and durable prints on a variety of substrates. Common ingredients in sublimation ink include water, organic solvents, dyes, and additives. Water serves as the primary carrier of the ink, facilitating the transfer of dye particles to the printing surface during the sublimation process. Organic solvents help dissolve dyes and enhance ink flow, while additives may include surfactants, stabilizers, and dispersants to improve ink performance and stability.

The precise composition of sublimation ink can vary depending on factors such as the intended application, printer model, and manufacturer specifications. By understanding the chemistry of sublimation inks, printers can make informed decisions about safety precautions, compatibility with substrates, and environmental considerations.

Tips for Minimizing the Risk of Exposure to Sublimation Ink

Minimizing the risk of exposure to sublimation ink is critical to maintaining a safe and healthy work environment. Whether you are a seasoned professional or new to the world of dye-sublimation printing, it is crucial to implement effective safety measures. By following the correct procedures and precautions, you can significantly reduce the likelihood of encountering the health hazards associated with sublimation ink.

From handling ink cartridges to operating printing equipment, every step provides an opportunity to reduce risk and protect yourself and others. In the following sections, we'll explore practical tips and best practices for minimizing exposure to sublimation ink, ensuring you can enjoy vibrant and durable prints without compromising safety.

In Conclusion

In summary, while sublimation inks offer unparalleled versatility and quality in printing applications, it is critical to recognize and address the associated health and safety considerations. By implementing appropriate safety protocols, adhering to regulatory standards and staying abreast of emerging trends, businesses can ensure a safe and sustainable working environment for everyone. If you want to know more about dye-sublimation ink or you are looking for a reliable dye-sublimation ink manufacturer, please contact us.

At FCOLOR, we pride ourselves on providing comprehensive solutions for all your inkjet ink needs. With state-of-the-art ink production lines and high-quality professional printers and consumables, we ensure that our customers receive best-in-class products for their printing requirements. Our line of inkjet printers adhere to the highest quality standards, guaranteeing reliable performance and durability. What sets us apart is our dedicated team of experienced experts who are ready to tackle any printing challenge you may face. Whether you are new to exploring the world of inkjet printing or an experienced dealer, we have the expertise to provide customized solutions that meet your specific needs and requirements.

As a professional custom inkjet printer and consumables manufacturer, with more than ten years of experience in the inkjet printer industry, FCOLOR has become a trusted partner for more than 50 customers every year. Our track record speaks for itself as we successfully support our customers, from beginners dabbling in inkjet printing to established resellers looking to expand their product range. In today's global economic and trade landscape, we recognize the importance of cultivating long-term relationships. That's why we're committed to working closely with our clients to create mutually beneficial partnerships that drive success and growth. Whether you are looking for reliable inkjet solutions or seeking to form a strategic partnership, FCOLOR can help you navigate the evolving printing industry and achieve your business goals.